For three years, Design Master Software has conducted a survey of engineers and designers in the MEP industry about whether or not they are using building information modeling (BIM) on their projects. Looking over three year’s worth of data, what is surprising is how little change there has been.

This article looks at the three things we observed in the data that were most interesting. The observations are related to projects that are using BIM for 3D collision detection and coordination (3D-BIM).

You can read a more detailed description of all the information we collected in the MEP 3D-BIM Survey 2012 Results article. In particular, the more detailed article looks at how BIM is being used for purposes other than 3D collision detection.

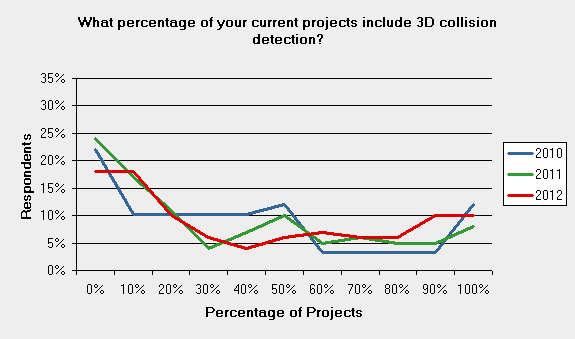

Observation #1: The number of projects using 3D-BIM is not changing.

This graph compares the percentage of projects that include 3D-BIM from the last three years. The lines for each year look pretty much the same.

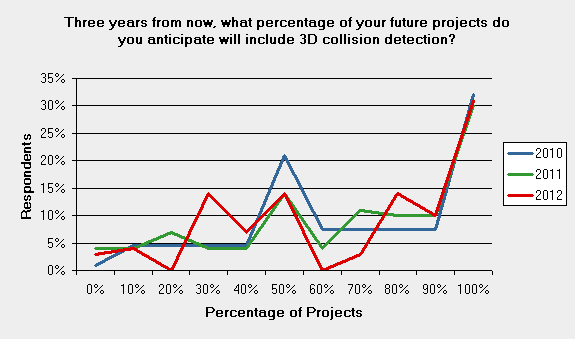

Observation #2: 3D-BIM is continually just three years away from becoming required on every project.

This graph compares the percentage of projects that respondents anticipate will use 3D-BIM three years in the future. Again, the line for each year looks pretty much the same.

Taken together, these two observations highlight a serious disconnect in the industry. Some projects are currently using 3D-BIM, but that number is not changing. Everyone expects that three years from now, most projects will be using 3D-BIM. But that future has not yet drawn any closer and is always three years away.

If the number of projects that involve 3D-BIM is not changing, why does everyone in the industry feel such pressure to transition to it, and why does everyone constantly anticipate it will be the standard in three years? We believe our next observation is the answer.

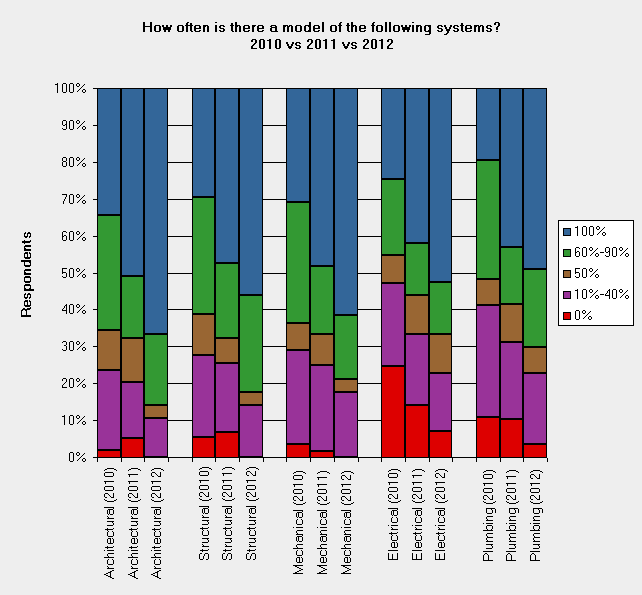

Observation #3: When a project uses 3D-BIM, the number of systems that are modeled is increasing.

The next graph displays how often a model of each system is provide when the project involves 3D-BIM. The blue portion of each bar represents the percentage of companies that see the specific system modeled 100% of the time. For all systems, it has consistently increased each year.

In the past, it was possible for a project involving 3D-BIM to not include all the systems in the building. For example, in 2010, over 20% of respondents never saw a 3D electrical model. Today, that number is less than 10%.

The transition that is happening in the industry is not that more projects are requiring 3D-BIM. That is staying the same.

Instead, the transition that is happening is that when a project requires 3D-BIM, everyone is being required to provide a model. Previously, certain systems were given a pass and not included. The focus was on the large systems that were the cause of most conflicts. Modeling just the structural and mechanical systems provided a lot of benefit even if the other systems were missing. Now that 3D models of those systems is standard, there is pressure and incentive to model the other systems, too.

The two conclusions we put forth based upon last year’s data both continue to be true:

Most projects will not be modeled in 3D. The number of projects using 3D-BIM will slowly increase, but it will not be as dramatic as our respondents expect. High profile projects featured in case studies, such as stadiums, hospitals, and towering skyscrapers, will continue to feature 3D collision detection. Routine buildings that do not benefit from 3D-BIM, such as strip mall remodels, banks, chain restaurants, and veterinarian offices, will not use it. These routine projects that do not require 3D-BIM will outnumber complicated projects that do.

Some projects will be modeled in 3D, and all disciplines will be required to produce a 3D model when this happens. Different parts of the industry have transitioned at different speeds to 3D-BIM. In the next year or two, when a project calls for a 3D model, it will be for the whole project. It will be increasingly unacceptable to have some disciplines not participate in this process.

Recommendations for the FutureGiven these conclusions, what should you do? Here is our advice: Be prepared to provide a 3D model for projects. If you are already working on projects in 3D, that’s great. You are already comfortable with where the industry is heading. If you are not comfortable working in 3D, continue to work toward getting comfortable. At some point, you are going to work on a project where your system is required to be modeled in 3D. When that happens, you need to be ready. Otherwise, you run the risk of losing work to other companies who use 3D-BIM. The specific program you use for this purpose–Design Master MEP, AutoCAD MEP, Revit MEP, or any of the other options–is not important. All can provide the necessary 3D model. What is important is that you are familiar with the program and know where to turn to when you have questions during the process. But don’t forget about projects that do not require 3D-BIM. Make sure you are constantly evaluating and improving your productivity on these other common projects. Hopefully, the same software you use for 3D-BIM includes other BIM features such as automated design calculations that can be used on all of the projects you work on. If not, you need to maintain two workflows, one for your 3D-BIM projects, and one for the your other projects. |

Further Reading

This article describes just the highlights of the survey. Read the MEP 3D-BIM Survey 2012 Results article for a complete discussion of all the results.